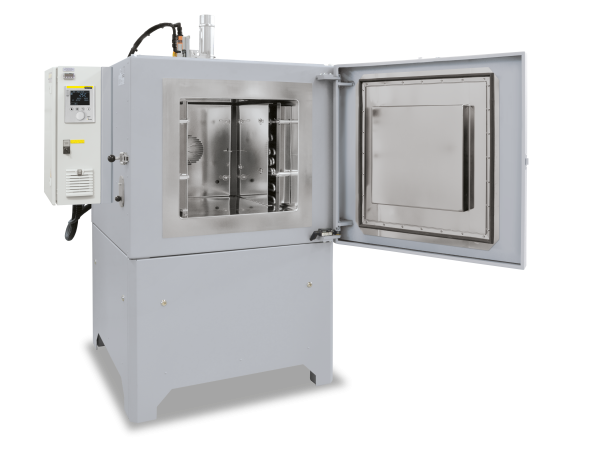

These chamber furnaces with air circulation are characterized by their extremely high temperature uniformity. Hence, they are especially suitable for processes such as annealing, crystalizing, preheating, curing, but also for numerous processes in tool making. Due to the modular concept, the forced convection furnaces can be adjusted to the process requirements by adding suitable equipment.

Standard Equipment

- Tmax 450 °C, 650 °C, or 850 °C

- Horizontal air circulation with optimum distribution through stainless steel baffles

- Swing door hinged on the right

- Temperature uniformity up to /− 4 °C according to DIN 17052-1 (NAT 15/65 and NAT 30/85 up to /− 5 °C) in the empty work space

- One frame sheet and rails for two additional trays included in the scope of delivery (NAT 15/65 and NAT 30/85 without frame sheet)

- Base frame included in the delivery, NAT 15/65 and NAT 30/85 designed as table-top model

- Controller B400/B410 (5 programs with each 4 segments)

- Defined application within the constraints of the operating instructions

- NTLog Basic for Nabertherm controller: recording of process data with USB-flash drive

Process Control and Documentation

As one of the world’s largest furnace manufacturers, Nabertherm has many years of experience in the design and manufacture of standardized and customer-specific control systems. All controls are characterized by a very high level of operating convenience and even the basic version has extensive basic functions. Depending on the requirements, the functions can be expanded and adapted to your needs. Professional software solutions for single or multiple furnace management as well as process and batch documentation based on our Nabertherm controllers complete the range.

Also for compliance with industry-specific standards that define process control and documentation, such as for example, the AMS 2750 F for aviation, the CQI-9 in the automotive industry or the FDA in the pharmaceutical industry we offer standardized solutions.

Additional Equipment

- Optimization of the temperature uniformity up to /− 3 °C according to DIN 17052-1 in the empty work space

- Air inlet and exhaust air flaps when used for drying

- Controlled fan assisted cooling

- Manual lift door (up to model NA 120/..)

- Pneumatic lift door

- Air circulation with speed control, recommendable for processes with light or sensitive charge

- Additional frame sheet

- Gas supply boxes different charging methods

- Feed and charging aids

- Charge control with documentation of the charge thermocouple

- Process control and documentation via VCD software package for monitoring, documentation and control